Conveyors/conveyor systems help with transportation and are also used as integrative elements of many operations, are an integral part of internal logistics. The basic types include roller, belt and chain conveyors. The individual types are suitable for various applications, and their use depends on the type of transported material, speed, method of use, etc.

One of the main advantages of conveyor technology is automatic sorting. The choice of the appropriate technology depends not only on the type and size of the material to be transported, but above all on the required sorting capacity.

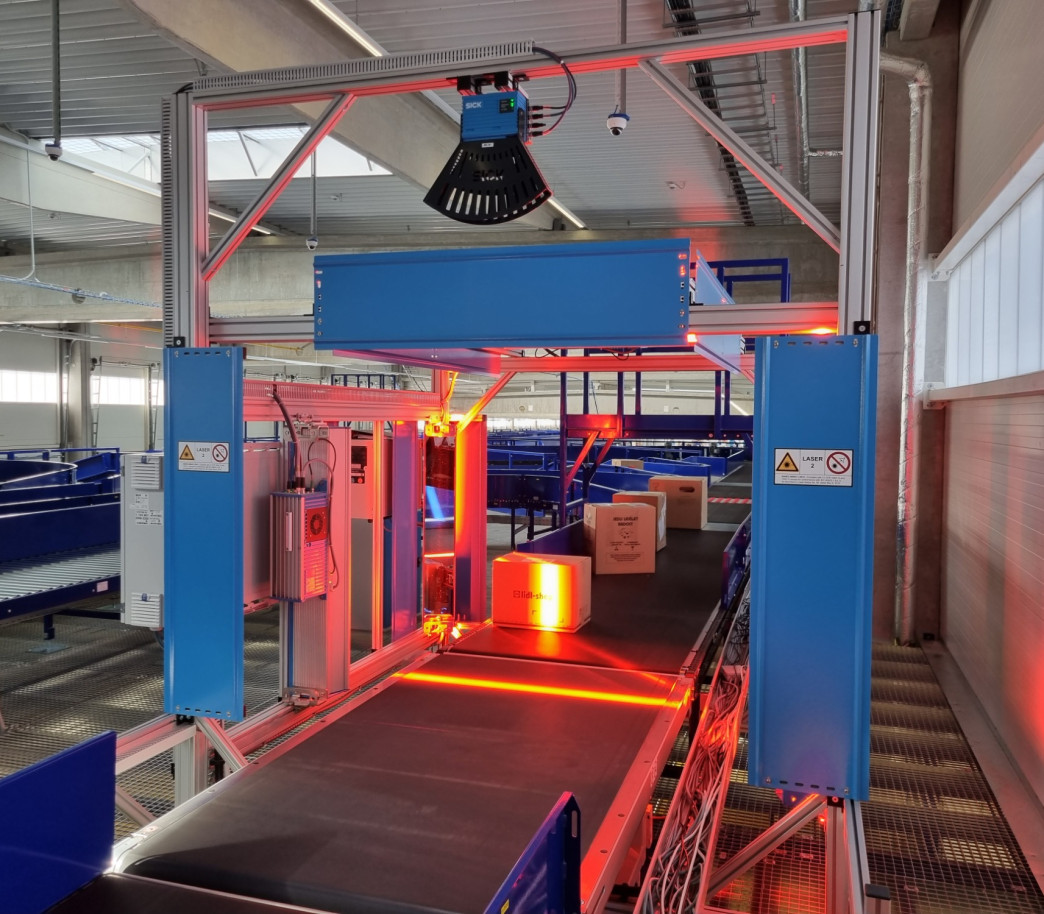

After unloading the goods, the process of receiving, inspection and loading follows. Conveyors not only ensure efficient transport, but also integrate key operations such as checking the number of pieces, measuring dimensions or volume and weighing. Identification by barcode or RFID technology is a matter of course.

At the beginning of intralogistics is usually the process of receiving material. Goods on pallets are unloaded using forklifts or hand trucks, which is safe and fast. For bulk goods, the unloading process takes longer and conveyors can speed up the process. Shorter extension modules (crawler or roller) are used for vans, while telescopic conveyors with a length of 4 to 16 metres are suitable for trucks and containers, which can unload 800 to 1,200 items per hour.

We also manufacture and supply accessories for our conveyor systems, including workbenches, steel structures and trolley stops. Integration of packaging and labelling machines can also be included. We tailor everything to the specific requirements and wishes of the customer.

Palletizers offer a range of advantages that allow them to be easily adapted to different types of products and operational conditions. Through automation and process optimization, they are capable of increasing production capacity and reducing operational costs. Additionally, these systems are often designed to allow for easy maintenance and the use of standard components, minimizing downtime and simplifying service.

Palletizers have a wide range of applications, whether for handling boxes, crates, bags, or other types of packaging. They can be complemented with various modules, such as empty pallet feeders, top board handling devices, or integrated conveyor systems.

Are you looking for an efficient and reliable conveyor system for your production or warehouse? We are here for you!

Our team of experienced experts is ready to provide you with a complete solution from design to installation.

Fill out the form below or contact us directly and we'll be happy to help you with your conveyor system needs.